Yet another set of wheels arrived this week. Number 4 if

you are counting. Blah. You’d think I would be excited but really I am pretty crabby

about the situation. Let me explain.

Most guys run 225/45-15s which is the biggest streetable

size there is but still a very wimpy tire for 400+ hp. And all the tires in

that size are expensive track orientated tires with only 7/32nds tread and a wear

rating of 200. So good luck getting even 10,000 miles out of them. At the rate mine are wearing I think 3 track days would completely consume a brand new set of them.

Well why are there no better street tires? The problem is there are

no factory production cars that use wide 15” tires to support wider sizes. For

example the Corvette has used wide low profile tires for that last couple

decades so the guys in Camaro and Mustang world have lots of great tires

available to them. But our little Miatas have no such benefactor.

The choice is to spend $800 to $1000 a year on the available wimpy tires or

doing lots of surgery to fit bigger, cheaper longer lasting street tires in it.

Anyone will tell you the disadvantages in height and weight out weigh the advantages in width but for me I just can't spend that much on tires every year.

OK but why exactly are you crabby? Because I am

digging into a major project that won't even give me half of what I want out of it. Sure it will be cheaper in the long run but for all this work I'd like at least 3 more inches of rubber on the ground and I can't even get half that because THERE ARE NO GOOD TIRES FOR V8 MIATAS! Humph. So here we go.

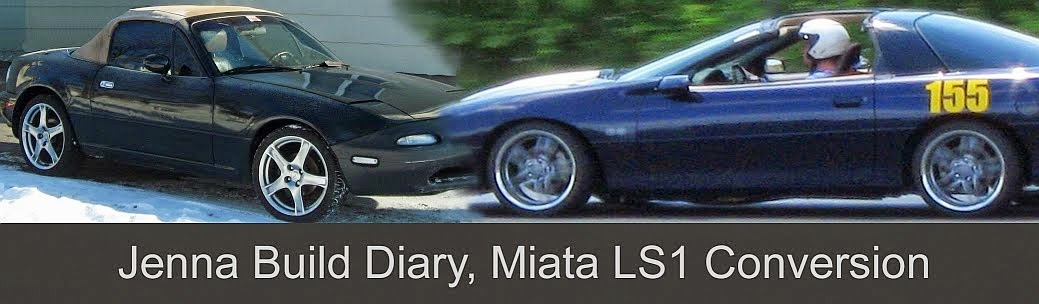

The new tires are 255/40-17s and this is what they look

like.

Yeah I know 5 spoke chrome are not what JDM Miatas are suppose to have but I don't care what the tuner kids say. I am an old muscle car guy so Jenna gets stripes, scoopes and chrome wheels and Charlie can fix her next time around. :-) Anyway as bad as the fit looks with the fender sitting right on the tire the real problem is behind the scenes. In a turn the tire hits the firewall where the frame rail gusset is. That is a major support structure I don’t take modifying lightly. So no cutting for sure... lets just say I induced a tolerance....

Obviously the fenders need lots of cutting too. I love owning a Sawzall!

The rear inner fender is a structural piece so it will get rolled around and welded back together.

The holes are to plug weld it clean as a factory spot weld!

OK now that you have cut half the poor car away... yeah I said it is major surgery!

You may recall I bought a set of flairs with the first set of wheels last summer and sold them both. Thing is I really don’t like the look of bolt on flares like that.

The rear inner fender is a structural piece so it will get rolled around and welded back together.

The holes are to plug weld it clean as a factory spot weld!

OK now that you have cut half the poor car away... yeah I said it is major surgery!

You may recall I bought a set of flairs with the first set of wheels last summer and sold them both. Thing is I really don’t like the look of bolt on flares like that.

Even painted they look like an after thought. I want something that looks like it is part of the car and belongs

there. Such flairs and wide body kits exist

but they are over $1500 so there is no chance I can do that. But I can do 100 bucks worth of sheet metal,

fiberglass and body putty to make my own.

Even painted they look like an after thought. I want something that looks like it is part of the car and belongs

there. Such flairs and wide body kits exist

but they are over $1500 so there is no chance I can do that. But I can do 100 bucks worth of sheet metal,

fiberglass and body putty to make my own. Of course I need a pattern and vision of what to make them look like and this is mine.

But you end up making 3 parts (plug, mold and flair) and only use one. Seemed like a waste so I decided to just do it in one pass by making a metal frame to support the shape I want the fiberglass matte to be. That is a all a mold really does and this way I gain support by having a metal frame inside the flare.

All those hours playing erector set finally pay off! I'll have to weld the frame to the car to really be able to work it to the shape I want but overall I think this will be a better way to go. Mind you I have never done either method and never seen anyone do this frame idea, but that is hardly a reason not to try it. What could go wrong? LOL!

Still no decision on the paint color but the poll was overwhelming blue and silver. My latest thought is hot rod matte black with gloss black stripes like so

Chrome looks good against it but my wheels are not this

bright. They are a black chrome and I think would really pop off the

satin black.

Not that I have already obtained this or am already perfect, but I press on to make it my own, because Christ Jesus has made me his own. Brothers, I do not consider that I have made it my own. But one thing I do: forgetting what lies behind and straining forward to what lies ahead, I press on toward the goal for the prize of the upward call of God in Christ Jesus.

Have a GREAT week!!